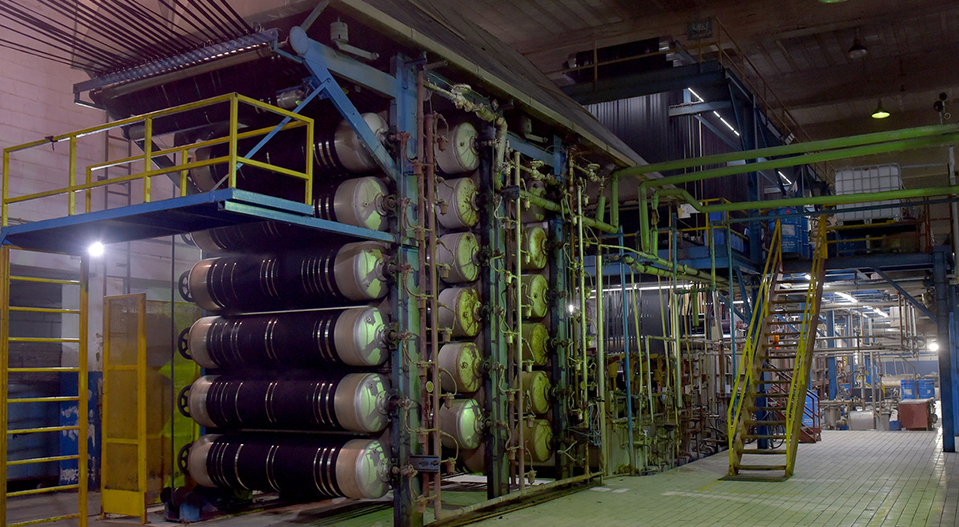

Spinning

Yarn spinning starts with the transfer of the cotton bales from warehouse chosen by a special software to the blowing room feeder as a initial step of yarn spinning process. From this point onwards, cotton undergoes preparation processes like cleaning, opening and blending with the content of other bales. During this process, the fibers which are too short are extracted.